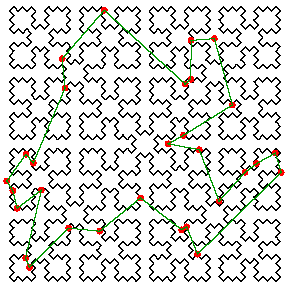

“Fresh out of college, with no background in finance, I learned high frequency trading (HFT) first hand while bootstrapping my startup from nothing to trading tens of millions of shares daily for a billion-dollar hedge fund. I’m starting this blog to discuss the technical challenges related to building world class HFT system, including developing the trading algorithms, handling the data feeds, building the high performance data structures, structuring the threading model, and designing the system for maximum reliability.”

Is it any surprise the similarity between a business focused on making money by watching money and any random business focused on making money by watching, I don’t know, tweets? The money watchers invest a lot of time & energy in building real time systems for delivering answers. The tweet watchers don’t care so much about real time currently. They’re ok with answers eventually rather than now. How much longer will this remain the case? Is there a future where real money is riding on immediate answers derived from tweets? Or from any random unit of “social media” from the fire hose? Regardless, it looks like the world of finance has a lot of the answers and WK’s High Frequency Trading Blog is a great behind the scenes look at how it could come together.

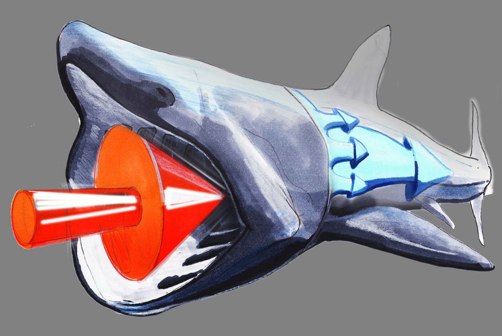

Make it yourself: A Thing-O-Matic Case Study

Makerblock receives a gift of colored pencils from his wife. But how to carry them? A few years ago he’d have to be happy with a trusty rubber band. But this is 2011. How does he solve his problem?

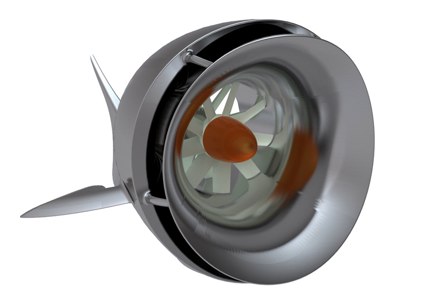

“After measuring them with my trusty calipers, I found they were 7mm from flat side to flat side on a cross-section. The above design uses a “width” of 7.2mm, which has resulted in an excellent fit. Each of the pencils falls/slides easily into a vacant hexagonal slot. The printed cap could be printed by increasing the “width” of the pencils. I’ve included the OpenSCAD file for anyone to peruse. Before you try to render it, please note it uses the MCAD library of shapes for OpenSCAD to create the hexagons.”

He feeds his CAD file to his Thing-O-Matic 3D printer and out pops his solution.

He adds: “Perhaps my favorite part about this design is that when you slide these little pencils into the case, you just know this case was custom made for these ten pencils.”